Study on Laser Conditioning Parameters of HfO2/SiO2 Mul tilayer Mirrors

Vol.07No.06(2017), Article ID:76893,13 pages

10.4236/ampc.2017.76019

Fu Dai1, Wenqing Shi2*, Baojian Yang3, Wuchao Huang1

1Department of Applied Physics and Materials, Wuyi University, Jiangmen, China

2College of Science, Guangdong Ocean University, Zhanjiang, China

3School of Mechanical and Electrical Engineering, Wuyi University, Jiangmen, China

Copyright © 2017 by authors and Scientific Research Publishing Inc.

This work is licensed under the Creative Commons Attribution International License (CC BY 4.0).

http://creativecommons.org/licenses/by/4.0/

Received: April 1, 2017; Accepted: June 12, 2017; Published: June 15, 2017

ABSTRACT

Laser conditioning is an effective method to improve the laser damage threshold of HfO2/SiO2 multilayer films prepared by electron beam evaporation. In this paper, some parameters that can affect the efficiency of laser conditioning were discussed. The result is that the maximum conditioning fluence should be less than 90% of its unconditioned laser induced damage threshold (LIDT) to avoid damage to the film. The laser beam increment between pulses and laser conditioning steps has a great influence on the improvement of damage threshold of HfO2/SiO2 multilayer high reflective coatings. The coverage of the light intensity on the defect should be as wide as possible, and the irradiation of light intensity should be as high as possible. The main mechanisms of laser conditioning of HfO2/SiO2 multilayer high reflective coatings may be the removal of Hf, Si and O ions and the removal of the defects in the films.

Keywords:

Laser-Conditioning, Defect, Laser Beam Increment, High Reflective Coatings

1. Introduction

A large number of optical components of different sizes are required in the ICF system, and these optical components include KDP frequency doubling crystals, lens, polarizers and various mirrors. Among them, the HfO2/SiO2 mirrors and the polarizing plate whose size of 0.5 m - 1.0 m are more than 1600 pieces [1] . At present, almost all of these large aperture optical components are prepared by electron beam evaporation. Due to the electron beam evaporation has high deposition rate, so that the coating density is relatively low, and the adhesion of thin film and substrate is poor. Therefore, the laser damage threshold of large aperture optical components in the existing conditions is still not significantly improved. Laser conditioning is an effective method to improve laser damage threshold of optical coatings, by using this method, a low repeated subthreshold laser irradiation was used to repair or improve the structure defects in coatings, so as to improve of laser damage threshold of optical coatings [2] [3] [4] [5] .

The experimental results show that the damage threshold of HfO2/SiO2 multilayer high reflective coating prepared by electron beam evaporation can be increased by 2 - 3 times by using laser conditioning [6] [7] [8] . This also provides an essential foundation for the development of the ICF system. Although laser conditioning method has been studied for a long time, but the mechanism still does not get consensus. Previous studies concentrated on laser conditioning to remove dust and moisture in the surface of the thin film, and to remove electronic defects in the films. But people generally believed that laser conditioning mechanism has something to do with removal of nodule defects on the surface of the film. The purpose of the laser conditioning is to select appropriate laser energy to irradiate on the surface of the sample to reduce the defect density of limiting of laser damage threshold of the sample.

In this paper, we studied the laser energy coverage characteristics of optical components surface defects during laser conditioning process and analyzed the influence of laser conditioning parameters to improve the laser damage threshold of optical components. The mechanism of laser conditioning to improve the damage threshold of optical thin film components and the method of laser conditioning energy selection were discussed.

2. Laser Conditioning Experiment

2.1. Experimental Device

The experimental device of laser conditioning is shown in Figure 1. The samples of HfO2/SiO2 multilayer high reflective coatings were prepared by electron beam evaporation on K9 glass with a thickness of 5 mm and 50 mm diameter, and the film is G/(HL) 11H2L/A. The conditioning laser is of the Gauss beam with an energy stability of better than 3%, a wavelength of 1064 nm, repetition rate of 10 Hz, pulse width of 7 ns, the output mode of TEM00, and the beam divergence angle of less than 25 μrad. We real time observed the surface of samples by using CCD. After focusing the lens with a focal length of 50 cm, the facula diameter is 1 mm (I0/e2). The spatial distribution of the laser pulse on the target surface is shown in Figure 2. The conditioning spot scanning method is raster scanning, as shown in Figure 3. Optical thin film damage test is in accordance with the international standard of ISO-11254 [9] , damage judgment by using CCD online observation. According to the requirements of NIF, if a single damage spot its size is less than 280 μm [10] , and the damage spot is not extended under the same energy laser irradiation, the spot is not damaged. In the process of laser conditioning, the distance between the laser beams determines the laser energy coverage characteristic of the surface of the sample. In most cases, the multi-step laser conditioning can improve the laser damage threshold of the optical

Figure 1. Schematic layout of laser conditioning facility.

Figure 2. The spatial distributing of laser pulse on samples.

components very well, when the junction intensity of front and rear spot is 90% of the peak intensity, as shown in Figure 3.

2.2. Experimental Methods

In the process of conditioning, the selection of laser energy should be based on the single pulse zero damage threshold E0 or S-on-1 damage threshold Es0 of HfO2/SiO2 multilayer high reflective coating. Based on Es0, S is usually taken as 100, that is, the same laser energy is used for 100 times in the same position of the optical components. S-on-1 damage threshold Es0 compared to 1-on-1 damage threshold E0 is much smaller because of the accumulation of micro damage of film surface. Therefore, the highest laser energy density selected for condi-

Figure 3. Depiction of raster-step laser conditioning process.

tioning is selected as 115% Es0 [11] when we used Es0 as the benchmark. But if we used E0 as the benchmark, the highest energy density selected for conditioning should below E0. In this paper, we used E0 as the benchmark for laser conditioning the high reflectance films prepared by electron beam evaporation, and chosen different laser energy density to measure 100 points on each sample, as shown in Figure 4. Then, we fitted the probability of damage of sample under different laser energy irradiation to obtain the zero damage threshold of the sample. After the laser conditioning, the single pulse zero damage threshold of the conditioned sample was obtained by the same damage test method.

3. Laser Conditioning Methods of HfO2/SiO2 High Reflective Coatings

3.1. The Maximum Laser Energy for Laser Conditioning

In order to avoid the damage of optical thin films with higher laser energy density during laser conditioning process, the highest laser conditioning energy density should be chosen in the range of safe energy density. At the same time, the laser energy density for laser conditioning should be chosen as high as possible to better eliminate or improve the defects in the film. In the experiment, a single step, four step and six step laser conditioning for different facula moving distance is carried out. The phenomenon occurring on film surface during laser conditioning process is shown in Figure 5. It can be seen that the film surface without any changes when the laser energy density for laser conditioning is below 60%E0. When the laser energy density is between 60%E0 - 90%E0, the film surface occurs some different degree of plasma sparks, as shown in Figure 6. This flash is beneficial for optical film to withstand continuous or higher energy laser irradiation. Some of film surfaces after flash cannot see any changes. Some

Figure 4. The laser damage threshold measurement methods of coatings

Figure 5. The phenomenon occurs on the coating during laser conditioning process.

Figure 6. The plasma flash in the film and its surface morphology after flash during laser conditioning process.

of film surfaces after flash form tens of microns of damage pits, these damage pits are more obvious nodule defect removal. When the laser energy density is above 90% E0, some damages will appear on the surface of some optical thin films, as shown in Figure 7. This damage is malignant, and the damage spot continues to expand under continuous pulse laser irradiation. When the damage occurs, we should stop scanning immediately, and then skip the damage zone to continue scanning, specific scanning method can refer to article [12] . Of course, we should try to avoid such damage in the laser conditioning process, therefore, the maximum energy for laser conditioning should not exceed 90% E0.

Figure 7. The plasma flash in the film and it’s damaged surface morphology during laser conditioning process.

3.2. The Relationship between Conditioning Parameters and Damage Threshold

In the process of laser conditioning, besides the coating process and the energy stability of the laser, the most important factors that affect the conditioning results are the laser energy and the step number of laser conditioning and the moving distance of the facula. These parameters will determine the laser energy range irradiated on the same region of film surface, and finally affect the laser conditioning results. In this paper, six different schemes were used for laser conditioning. Scheme 1, using the four step of laser conditioning mode, the moving distance of the facula is about 0.23 mm, that is, the 90% of laser energy coverage. The single pulse zero damage threshold of the optical coatings that we observed is almost 22.4 ± 1.2 J/cm2 before laser conditioning. The conditioning laser energy density is 13.44 J/cm2, 15.68 J/cm2, 17.92 J/cm2 and 20.16 J/cm2 respectively. Some plasma flash appeared on the surface of the film during laser conditioning process, but no damage was observed. The single pulse zero damage threshold of the conditioned coatings is almost 28.22 J/cm2, and the laser damage resistance is increased by about 26% compared with that before conditioning, as shown in Figure 8.

Scheme 2, using the single step of laser conditioning mode with laser energy coverage of 97.5%, the moving distance of the facula is about 0.115 mm, and the conditioning efficiency is the same as that of scheme 1. The laser energy density for conditioning is almost 21.3 J/cm2, a dense plasma flash appeared on the surface of the film during laser conditioning process, but no damage occurred. The damage threshold of conditioned thin film element is almost 29.5 J/cm2, which is increased by about 31.5% compared with that before conditioning. Scheme 3, using the six step of laser conditioning mode, the moving distance of the facula is about 0.23 mm , the conditioning laser energy density are 11.4 J/cm2, 13.53 J/cm2, 16.02 J/cm2, 18.23 J/cm2, 20.51 J/cm2 and 21.8 J/cm2 respectively. The laser damage threshold of the conditioned film is almost 33.9 J/cm2, which is increased by about 51% compared with that before conditioning. Scheme 4, using the single step of laser conditioning mode with laser energy coverage of 98%, the moving distance of the facula is about 0.1 mm. The conditioning laser energy density is almost 22.7 J/cm2. The damage threshold of conditioned thin film

Figure 8. The Laser damage threshold of coatings after laser conditioning.

element is almost 34.5 J/cm2, which is increased by about 54% compared with that before conditioning. Scheme 5, using the single step of laser conditioning mode with laser energy coverage of 98.4%, the moving distance of the facula is about 0.09 mm. the conditioning laser energy density is 19.3 J/cm2. The damage threshold of conditioned thin film element is almost 35.8 J/cm2, which is increased by about 59.7% compared with that before conditioning. Scheme 6, using the two step of laser conditioning mode with laser energy coverage of 98.4%, the moving distance of the facula is about 0.09 mm. The conditioning laser energy density is 18.3 J/cm2, and 21.5 J/cm2 respectively. The damage threshold of conditioned thin film element is almost 40.5 J/cm2, which is increased by about 81% compared with that before conditioning.

From the experimental results of the above six schemes, it can be seen that the choice of laser conditioning parameters has a great influence on the improvement of damage threshold of HfO2/SiO2 multilayer high reflective coatings. Because of the directivity of laser beam and the reset precision of laser conditioning platform may lead to the displacement of the conditioning light spot and change the intensity of illumination on the defect. The high light intensity will damage the defects, but the low light intensity can’t repair the defects. It is difficult for us to analyze the mechanism of laser conditioning and select the appropriate conditioning parameters. Therefore, it is necessary to analyze whether the error of the moving spot has a great influence on the radiation intensity of defects. In this experiment, the laser beam divergence angle is 25 μrad, the distance of L between the focusing lens and the exit pupil is almost 2 m, the distance between the target and the lens is about 47 cm, and the lens focal length is almost 50 cm. The spot offset error x caused by the directivity of the laser beam is satisfied

, that is, x = 3 μm. Because of the positioning precision of the laser

, that is, x = 3 μm. Because of the positioning precision of the laser

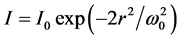

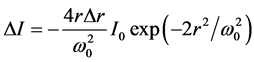

conditioning platform is almost 0.1 μm, and the reset precision is about 1 μm. Therefore, the total spot offset error is almost ±4 μm in the process of laser conditioning. By the intensity distribution of the Gauss beam  (

( = 0.5 mm is the light spot radius where the light intensity decreased to

= 0.5 mm is the light spot radius where the light intensity decreased to

), we can get

), we can get , When r = ±0.2 mm, the light

, When r = ±0.2 mm, the light

intensity change rate caused by the deviation of light spot is up to the maximum 0.92% , as shown in Figure 9.

Therefore, The light intensity variation caused by the light spot moving error has little effect on the light intensity irradiating on the defects in the process of laser conditioning (usually, the effective light intensity of repairing the defects is above 60%I0). It can be seen from the analysis of the experiment results of Scheme 1, Scheme 2, Scheme 3 and Scheme 5 that the single step laser conditioning has better effect on improving the laser damage threshold than the multi-step laser conditioning under the same conditioning efficiency. The six step conditioning effect is better than the four step conditioning effect. In the paper [12] , we analyzed in detail the light intensity coverage of defects on the different facula moving distance. With 20 μm defect as an example, in scheme 1, the light intensity coverage of the defect covers 43.5% of the total light intensity; in Scheme 2, the light intensity coverage of the defect covers 52.67% of the total light intensity; in Scheme 3, the light intensity coverage of the defect covers 55.52% of the total light intensity; in Scheme 4, the light intensity coverage of the defect covers 57.6%% of the total light intensity; in Scheme 5, the light intensity coverage of the defect covers 61.4% of the total light intensity; in Scheme 6, the light intensity coverage of the defect covers 81.28% of the total light intensity.

Figure 9. The max laser intensity variation induced by spot offset error.

The results show that the effect of laser conditioning is related to the light intensity range on the defect, the number of spot irradiation and the highest light intensity irradiation on the defect. Because of the distance of spot movement during the single step conditioning process is reduced. The probability of irradiation with the same energy density is reduced. Therefore, the coverage of the light intensity on the defect and the coverage of the higher light intensity are increased, which is closer to the effect of R-on-1 laser conditioning. Therefore, the effect of single step conditioning is better than that of multi-step conditioning under the same laser conditioning efficiency. Compared with the four step conditioning, the six step conditioning has no significant increase in the range of light intensity. However, due to the increase of the number of spot irradiation, the laser conditioning effect was improved obviously. In scheme 6, both defect coverage intensity and high intensity irradiation times or the coverage of the higher light intensity compared to the previous five options are greatly improved, therefore, the maximum damage threshold of conditioned film reached 181% E0. The experimental results show that the effect of laser conditioning is related to the coverage of light intensity. Therefore, in order to improve the efficiency of laser conditioning, the coverage of the light intensity on the defect should be as wide as possible, and the irradiation of light intensity should be as high as possible.

4. Discussion on the Mechanism of Laser Conditioning

Although there is still no uniform understanding of the laser conditioning mechanism, it is generally believed that the laser conditioning effect is related to the defect removal in the film. In the experiment, we can clearly observe the peak signal attenuation on the conditioned defect by using photothermal microscopy [13] . A similar plasma flash was observed in our experiments. The surface of the thin film appeared some small pits whose diameter of 10 - 20 μm after plasma flash, which cannot be expanded under the continuous or higher energy density laser irradiation. This is a more obvious defect removal morphology, as shown in Figure 10.

Another plasma flash phenomenon was also observed when the sample is irradiated by a lower subthreshold laser. This kind of flash is produced when the laser energy increases gradually, and with the increase of the laser energy, the number, frequency and intensity of the flash increase. It is worth noting that some parts of the surface of the film appear flash in low energy laser irradiation, but the flash will no longer happen when under the higher energy laser irradiation until the damage occurs. The results show that this kind of flash occurring on the surface of film is beneficial to the improvement of the damage threshold of the coatings. In our experiment, the laser repetition frequency is 10 Hz, so, there is no temperature accumulation effect on the film surface, that is, only single pulse laser energy can lead to film damage or defect repairing. It can be assumed that there is a certain laser energy density range of E± for each defect repairing. If the laser energy density is within the range of E− ~ E+, the defects can

Figure 10. The type morphology of coatings after flash during laser conditioning process.

be eliminated or repaired or improved in the form of plasma flash. If the laser fluence is less than E−, it will not have any effect on the defect. If the laser fluence is higher than E+, there will be damage or micro damage on the surface of the film, and this damage is irreversible, in subsequent irradiation of the laser pulse, the damage spot will be further expanded, resulting in a catastrophic damage. The defects in the coatings according to their origin can be classified as nodule defects and Hf, Si and O, ect. atoms or ions defects formed in the process of coatings. Because of the low degree of binding of the thin film and nodule defects, it can be removed with a low energy laser in the laser conditioning process, leaving a small pit. This crater has little effect on the surrounding film, so it can withstand higher energy laser irradiation, as shown in Figure 11. Under the laser irradiation of 60% E0 - 90% E0, Hf, Si and O atoms in the coatings react to form ion scattering, and then appear with a certain intensity of plasma flash. After the flash, no change was observed on the surface of the film, but the internal mode of the atomic or ion in the film was changed, as shown in Figure 12. Therefore, the film after the flash can withstand higher energy density laser irradiation. However, the sub-micron-sized nodule defects in the coatings are more dangerous. Because of these defects are completely surrounded by optical films, and they are well combined with optical films. Therefore, it cannot be removed under a lower laser energy density irradiation. When the laser energy reaches a certain value, the defect will expand, and finally be detonated to break through the film, as shown in Figure 13. Even if the defect is removed in the laser conditioning process, it will also affect the surrounding film. Under irradiation of the subsequent laser pulse, the film will be further damaged for the adhesion property and the structure variation. If this kind of damage produced in the process of laser conditioning, laser scanning should skip the damaged area. When the laser conditioning is completed, a laser with low energy density is used to repair the damaged area.

Figure 11. Schematic diagram of wiping out the nodule on the coatings.

Figure 12. Schematic diagram of wiping out the Hf, Si, O atom and ion in the HfO2/SiO2 coatings

Figure 13. Schematic diagram of wiping out the submicron defect in the coatings.

5. Conclusions

Laser conditioning is an effective method to improve the laser damage threshold of HfO2/SiO2 multilayer films prepared by electron beam evaporation. Analysis of experimental results of laser conditioning for HfO2/SiO2 multilayer high reflective coatings, and it can be seen that the spot moving distance of laser conditioning is not limited to the overlapping of 90% I0, but to a reasonable choice according to the characteristics of defects introduced during the coating process. In this paper, the laser damage threshold of the HfO2/SiO2 multilayer high reflective coatings was improved 81% by two step laser conditioning with the spot overlap of 98.36% I0. The experimental results also show that the single step conditioning with the same conditioning efficiency has better effect on improving the laser damage threshold than that of multi-step conditioning. The highest laser energy selected for laser conditioning should be as high as possible, but cannot damage the film, and the general choice is less than 90% E0. The mechanism of laser conditioning of optical thin films is discussed. The main mechanism of laser conditioning is the removal of Hf, Si and O ions and the removal of the defects in the films.

The choice of laser conditioning parameters is also affected by the size of defects, and different defect sizes need to adopt different conditioning parameters. In order to select the appropriate laser conditioning parameters, the defect characteristics of the samples must be analyzed before laser conditioning. The laser scanning mode has a great influence on the laser conditioning efficiency. Therefore, the laser energy, the moving distance of laser spot and the laser scanning mode should be taken into consideration when choosing the laser conditioning parameters.

Cite this paper

Dai, F., Shi, W.Q., Yang, B.J. and Huang, W.C. (2017) Study on Laser Conditioning Parameters of HfO2/ SiO2 Mul tilayer Mirrors. Advances in Ma- terials Physics and Chemistry, 7, 242-254. https://doi.org/10.4236/ampc.2017.76019

References

- 1. Kozlowski, M.R., Wolfe, C.R., Staggs, M.C., et al. (1989) Large Area Laser Conditioning of Dielectric Thin Film Mirrors. Laser-Induced Damage in Optical Materials, Proceedings of SPIE, 1438, 376-390.

- 2. Jena, S., Tokas, R.B., Kamble, N.M., et al. (2014) Optical Properties and Laser Damage Threshold of HfO2-SiO2 Mixed Composite Thin Films. Applied Optics, 53, 850-860.

https://doi.org/10.1364/AO.53.000850 - 3. Wolfe, C.R., Kozlowski, M.R., Campbell, J.H., et al. (1989) Laser Conditioning of Optical Thin Films. Laser-Induced Damage in Optical Materials, Proceedings of SPIE, 1438, 360-375.

- 4. Fornier, A., Cordillot, C. and Ausserre, D. (1993) Laser Conditioning of Optical Coatings: Some Issues in the Characterization by Atomic Force Microscopy. Laser-Induced Damage in Optical Materials, Proceedings of SPIE, 2114, 145-162.

- 5. Ling, X.L., Zhao, Y.A., Li, D.W., et al. (2010) Laser Conditioning of High-Reflective and Anti-Reflective Coatings in Vacuum Environments. Optics Communications, 283, 2728-2731.

https://doi.org/10.1016/j.optcom.2010.03.014 - 6. Stolz, C.J., Sheehan, L.M., Maricle, S.M., et al. (1998) A Study of Laser Conditioning Methods of Hafnia Silica Multilayer Mirrors. Laser-Induced Damage in Optical Materials, Proceedings of SPIE, 3578, 1-9.

- 7. Zhao, Y.A., Wang, T., Zhang, D.W., et al. (2005) Laser Conditioning and Multi-Shot Laser Damage Accumulation Effects of HfO2/SiO2 Antireflective Coatings. Applied Surface Science, 245, 335-339.

https://doi.org/10.1016/j.apsusc.2004.10.028 - 8. Sheehan, L., Kozlowski, M.R., Rainer, F., et al. (1993) Large-Area Conditioning of Optics for High-Power Laser Systems. Laser-Induced Damage in Optical Materials, Proceedings of SPIE, 2114, 559-568.

https://doi.org/10.1117/12.180939 - 9. Laser and Laser Related Equipment Determination of Laser Induced Damage Threshold of Optical Surface. ISO 11254-1, 1995.

- 10. Stolz, C.J., Sheehan, L.M., Maricle, S.M., et al. (1999) A Study of Laser Conditioning Methods of Hafnia Silica Multilayer Mirrors. Laser-Induced Damage in Optical Materials, Proceedings of SPIE, 3578, 144-152. https://doi.org/10.1117/12.344419

- 11. Sheehan, L.M., Kozlowski, M.R. and Tench, B. (1997) Full Aperture Laser Conditioning of Multilayer Mirrors and Polarizers. Laser-Induced Damage in Optical Materials, Proceedings of SPIE, 2633, 457-463. https://doi.org/10.1117/12.228294

- 12. Dai, F. and Yang, L.M. (2012) Study on Laser Energy That Irradiate the Defect during Laser Conditioning Process. High Power Laser and Particle Beams, 24, 1385- 1390.

https://doi.org/10.3788/HPLPB20122406.1385 - 13. Papandrew, A.B., Stolz, C.J., Wu, Z.L., et al. (2001) Laser Conditioning Characterization and Damage Threshold Prediction of Hafnia Silica Multilayer Mirrors by Photothermal Microscopy. Laser-Induced Damage in Optical Materials, Proceedings of SPIE, 4347, 53-61.

https://doi.org/10.1117/12.425049

上一篇:Elaboration and Characterizati 下一篇:Thermal Behavior and Magnetic

最新文章NEWS

- Photophysical, Electrochemical and Photovoltaic Properties of Porphyrin-Based Dye Sensitized Solar C

- Copper Adsorption from Wasterwater Using Bone Charcoal

- Elaboration and Characterization of Glasses and Ceramic-Glasses within Theternary Diagram Li2O-Cr2O3

- Effect of Precipitation on the Hardness of Ternary Metallic Glass

- Study on Laser Conditioning Parameters of HfO2/SiO2 Mul tilayer Mirrors

- Thermal Behavior and Magnetic Properties of Nd-Fe-B Based Exchange Spring Nanocomposites Nd4-xTbxFe8

- Metal-Insulator Transition of Peierls Type in Quasi-One-Dimensional Crystals of TTT2I3

- The Effect of Nitrogen Gas Flow Rate on the Cr-Containing DLC (Diamond-Like Carbon) Coating by AEGD

推荐期刊Tui Jian

- Chinese Journal of Integrative Medicine

- Journal of Genetics and Genomics

- Journal of Bionic Engineering

- Pedosphere

- Chinese Journal of Structural Chemistry

- Nuclear Science and Techniques

- 《传媒》

- 《中学生报》教研周刊

热点文章HOT

- Effect of Trisodium Citrate on the Properties of Electrodeposited Cu2ZnSnS4 (CZTS) Layers on ZnS Thi

- Metal-Insulator Transition of Peierls Type in Quasi-One-Dimensional Crystals of TTT2I3

- Scanning Based Induction Heating for AISI 4340 Steel Spline Shafts-3D Simulation and Experimental Va

- Attack of Tunisian Phosphate Ore by a Mixture of Sulfuric and Phosphoric Acid: Thermochemical Study

- The Effect of Nitrogen Gas Flow Rate on the Cr-Containing DLC (Diamond-Like Carbon) Coating by AEGD

- Discovery of β-HIO3: A Metastable Polymorph of HIO3

- Study of the Thermal, Rheological, Morphological and Mechanical Properties of Biocomposites Based on

- Effects of Residual Oxygen in the Degradation of the Performance of Organic Bulk Heterojunction Sola